Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

Cable Tray Scaffold Roll Forming Machine Overview Cable tray and Scaffold are similar profiles with the same roll forming process. raw material and finished product. Material: Q195, Q235 hot rolled Steel strip thickness: 1.25~2mm Steel strip width: 200-950mm Finished Product Cable tray: 100mm...

Cable Tray Scaffold Roll Forming Machine Overview

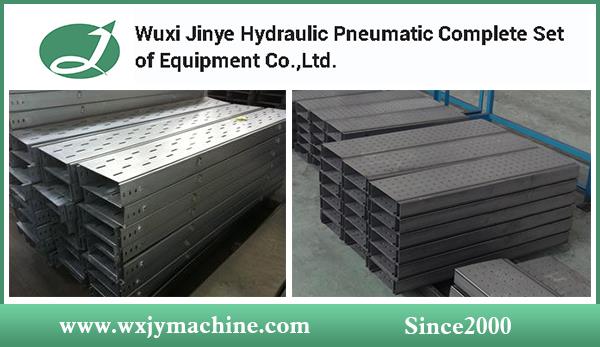

Cable tray and Scaffold are similar profiles with the same roll forming process.

raw material and finished product.

Material: Q195, Q235 hot rolled

Steel strip thickness: 1.25~2mm

Steel strip width: 200-950mm

Finished Product

Cable tray: 100mm width, 1.25-2.0mm thickness, 40-95mm height

Specifically: width 100, 150, 200, 250, 300, 350, 400, 450, 500, 550, 600mm

height: 50, 65, 80mm

Scaffold: 1.25-2mm, B = 200-333mm, H=42.5mm

Length: minimum 2000mm

The popular profiles as below:

Roofing panel forming machine

C,Z purlin roll forming machine

Guardrail cold forming line

Culvert corrugated panel forming machine

Elevator parts cold forming machine

Photovoltaic stent roll forming machine

Cable tray roll forming machine

Scaffold foot plate forming machine

Racking profiles forming machine

Cable Tray & Scaffold Machine

Structure: cantilever universal forming stands, with width and height adjustable, chain transmission, composed of combined rollers, linear width adjusting mechanism, gearboxes of left side and right side, speed reduce and AC motor.

After punching and cutting, steel plate go through 18-22 forming stations.

One complete set of combined rollers can make all profiles.

Forming shafts: Ф65mm

Motor: 5.5KW AC, 4sets

Forming speed: 8-12m/min

Application

Steel Profiles are widely used in many industries such as construction, house decoration, solar energy mounting system, elevators, automobiles, etc. We design and make steel profile roll forming machines according to client’s profile drawings.

Our Advantages

a. Fully Customerized Design And Production:

Each machine is designed and made fully according to customer’s requirements, to reach complete customerization, we usually face to face discuss with customers confirming each technical detail, or communicate with customers by emails or online conversation with each technical document checked and confirmed by customers.

Our technicians make drawings of each machine according to signed specification.

The machining, heat treatment, grinding, assembly of each part are strictly processed under production schedule.

b. Strict Testing Procedures:

We check the parameters of each unit according to order details.

We test each motor, each electric cabinet, each valve.

We measure each machine dimensions and weight for shipment.

c. Best After-Sale Service:

We provide foundation drawing for civil works, electric wiring drawing, hydraulic/ pneumatic schematic drawing, operation & maintenance manual.

We can send technicians to customer’s plants to help install and debug machines.

The customer should get installation conditions ready before our technicians come, buy round trip air tickets, provide food & lodging.

The machine guarantee period is one year after end of commissioning.

d. Safe Packing:

Anti-rust oil be spread on machines before shipping.

Electric cabinets covered with plastic bag.

Small parts, valves, hoses are packed in wooden case.

FAQ

1.What is your minimum order quantity, can you send me samples?

A: Our minimum order is 1 set machine, each machine is customerized, thus we don’t have sample to send, however, we can send you catalog, warmly welcome you to visit our company.

2.Which level of quality are your products?

A: We don’t say our machine quality is the best, our aim is to supply most suitable machine at most reasonable price." functional, safe, economical" principles keep our company everlasting.

3.As the shipping period will take long time, how can you make sure the machine won’t be broken?

A: Our machine is film wrapped, to make sure the machine can be delivered to our customer in safe conditions, we fix the machine in the container by steel wires/ ropes.

4.About the after-sale service, how can you solve the problems occurred of your overseas customer in time?

A: The warranty period of our machine is 12 months. Within the period, if machine problem is due to quality fault, we will replace parts for free. The moment we know the machine problem from customer, we will firstly tell the customer the fastest available schedule, then bring solution or send out parts as scheduled.