Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

Flat Steel Machine Overview Hot rolled flat bars consume a lot of power and productivity is low, in actual production, many customers choose to make flat bars from slit HR coils by the uncoiling, leveling, cutting to length and edge milling process. As well, in many cases when edge milling is...

Flat Steel Machine Overview

Hot rolled flat bars consume a lot of power and productivity is low, in actual production, many customers choose to make flat bars from slit HR coils by the uncoiling, leveling, cutting to length and edge milling process. As well, in many cases when edge milling is not necessary, customers can make multiple flat bars directly from wide HR coil, we make this kind of flat steel machine.

We supplied five flat steel machines to Ghana, Nigeria, Sudan, Philippines and South Africa.

Input Mother Coil

Coil thickness: 0.5~6mm

Coil width: 200~500mm

Material of coils: Q195,Q235A, B hot-rolled low carbon steel

Coil ID: φ400-550mm

Coil OD: ≤φ1400mm

Coil weight: ≤5T

Flat Bar Machine Parameters

Slitting precision: width tolerance ±0.2mm, edge bending: GB709-88, GB704-88

Max slit number: 12 strips

Slitting speed: 0-17m/min

Slitting shaft: φ160 mm

Slitting knives: ID160×OD280 (along with machine, 26pcs supplied; if customer wants to get 17-40mm wide strips, we can help order the knives buyer must pay for.

Material of slitting knives: 6CrW2Si, HRC55°—60°

Leveling roller: φ125mm

Material of leveling rollers: 40Cr, surface hardness: HRC52-55°

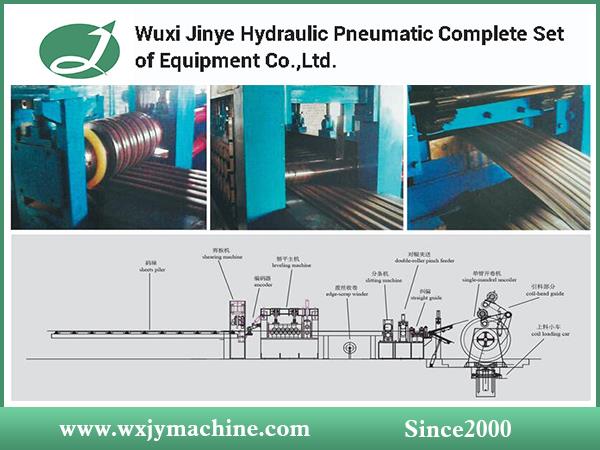

Technical Flow

Coil-loading car→ single mandrel uncoiled→ pinch feeder→ side guide & press→ disc slitting → scrap reeler→ transmission table→ leveler→ cut-to-length fixing→ shear→ stacker.

Equipment Characteristics

1.Advanced computer image processing system, a friendly user interface;

2.A overall grading by size, shape, color, defects(determined by sorting varieties);

3.The treated fruit surface color is bright, with the same size;

4.Fast and accurate sorting per customer request;

5.Improve the added value of fruit, and to extend shelf life.

Our Advantages

a. Extensive Rich Experiences:

We are specialized in the steel plate processing machines especially slitting machine & cut to length machines for over 15 years.

b. High Quality Raw Material And Standard Parts:

We choose high quality materials from reliable supply channel.

We select famous parts like hydraulic valves, pneumatic parts, electric parts, bearings, bolts, etc. We are capable of designing and making the hydraulic system.

c. Delivery Time:

The machine design and production need a production cycle.

For small machine, usually 45-60 days.

For big machine and production line, usually 90-120 days.

d. Safe Packing:

Anti-rust oil be spread on machines before shipping.

Electric cabinets covered with plastic bag.

Small parts, valves, hoses are packed in wooden case.

FAQ

1.If I will need to stay in your place for a few days, can you book hotel for me?

A: It is my pleasure to book hotel for you.

2.Which level of quality are your products?

A: We don’t say our machine quality is the best, our aim is to supply most suitable machine at most reasonable price. “functional, safe, economical” principles keep our company everlasting.

3.As the shipping period will take long time, how can you make sure the machine won’t be broken?

A: Our machine is film wrapped, to make sure the machine can be delivered to our customer in safe conditions, we fix the machine in the container by steel wires / ropes.