Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

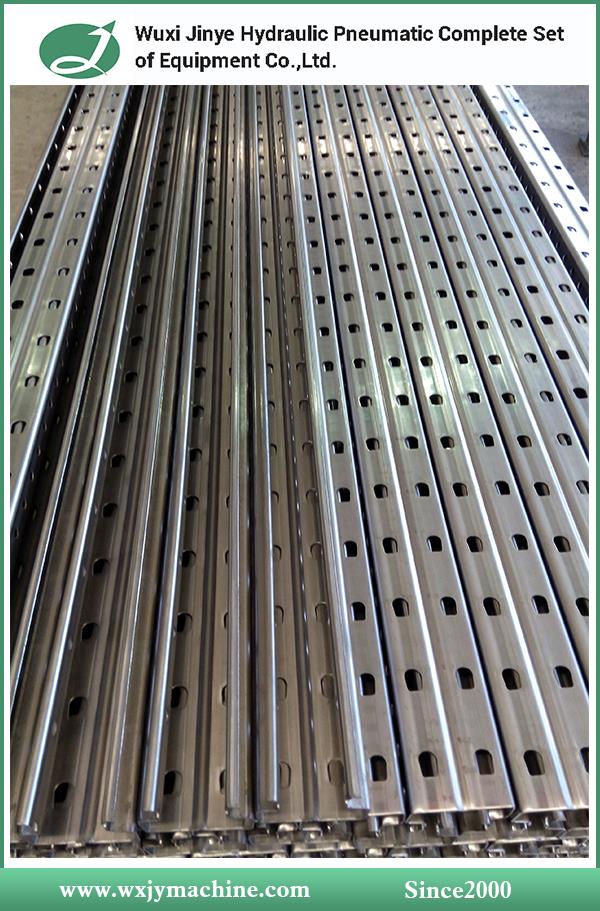

Racking Omega Upright Column roll forming machine introduction The roll forming machine is to make racking upright columns (total 3 profiles), after threading, the machine can automatically open steel coil, servo feeding & holes punching, roll forming, cutting and output finished upright...

Racking Omega Upright Column roll forming machine introduction

The roll forming machine is to make racking upright columns (total 3 profiles), after threading, the machine can automatically open steel coil, servo feeding & holes punching, roll forming, cutting and output finished upright product.We design and make steel profile roll forming machines according to client’s profile drawings.

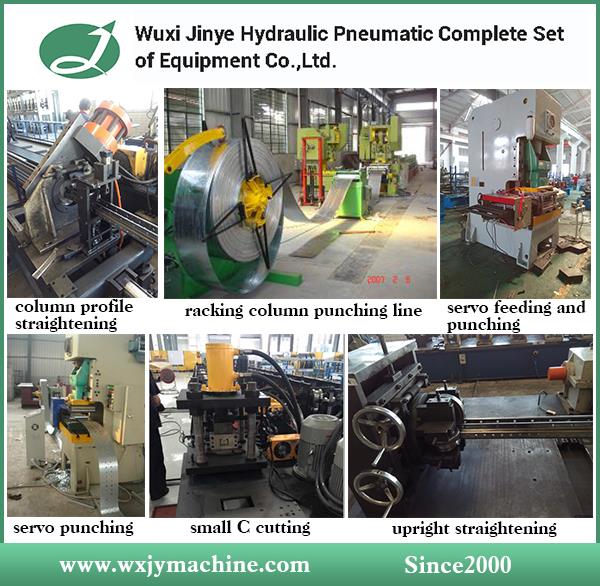

Composition and Flow of the Omega upright roll forming line

Uncoiler--- servo feeding and punching--- entry table--- roll forming machine--- straightening--- pneumatic track shear--- electric control--- output table

Main parameters of the Omega Racking Column forming machine

Input Material - steel coil:

Coil material: Q235B

Coil thickness: ≤2mm

Coil width: ≤300mm

Coil inner diameter: φ480~φ520mm

Coil outer diameter: ≤φ1300mm

Coil weight: max 3T

Finished product - upright:

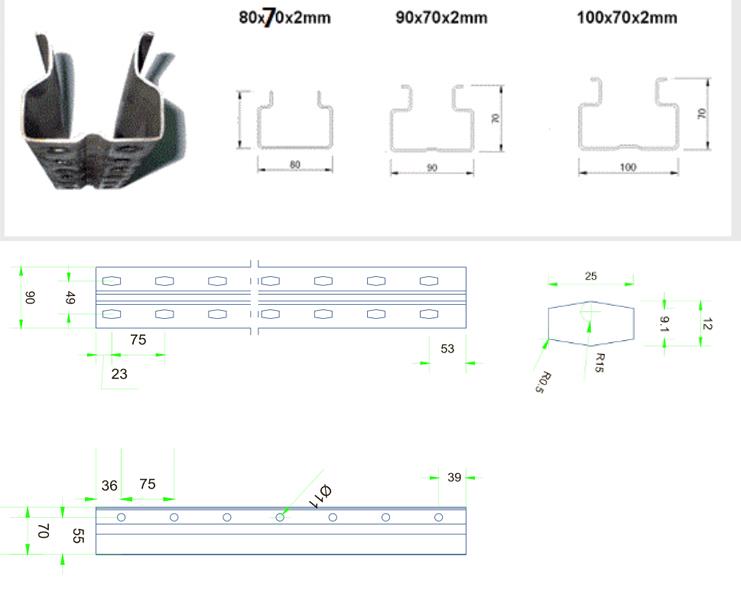

Upright size: 80*70*2 90*70*2 100*70*2

Cutting length: adjustable according to customer demand

Length tolerance: ±1mm

Profile tolerance: according to customer’s profile drawing

Forming parameters:

GY160 roll forming machine, 20 forming stations

Shafts: 40Cr, Ф80mm, quenched & tempered treatment

Rollers: Cr12, quenched surface hardness HRC58-60

15KW x 2sets AC frequency control motors, ZQ500 speed reducers and gearboxes drive

The profile change is realized by changing spacers.

Forming speed: 1-15m/min

Power source: 380V, 50Hz, 3phases

Total installation power: about 52KW

Land occupation: about 35m length x 3m width

Our Advantages

a. Extensive rich experiences:

We are specialized in the steel plate processing machines especially slitting machine & cut to length machines for over 15 years.

b. Fully customerized design and production:

Each machine is designed and made fully according to customer’s requirements, to reach complete customerization, we usually face to face discuss with customers confirming each technical detail, or communicate with customers by emails or online conversation with each technical document checked and confirmed by customers.

Our technicians make drawings of each machine according to signed specification.

The machining, heat treatment, grinding, assembly of each part are strictly processed under production schedule.

c. High quality raw material and standard parts:

We choose high quality materials from reliable supply channel.

We select famous parts like hydraulic valves, pneumatic parts, electric parts, bearings, bolts, etc. We are capable of designing and making the hydraulic system.

d. Strict testing procedures:

We check the parameters of each unit according to order details.

We test each motor, each electric cabinet, each valve.

We measure each machine dimensions and weight for shipment.

FAQ

1.How can I get to your factory?

A: Our city Wuxi is near to Shanghai. You can get off plane at Pudong or Hongqiao airport in Shanghai, then come to Wuxi by fast train for 40minutes. You can take fast train from Beijing to Wuxi, 5 hours. You can come to Wuxi Shuofang Airport by plane. We can pick you up from Wuxi stations, airport, even in Shanghai airport.

2.About the after-sale service, how can you solve the problems occurred of your overseas customer in time?

A: The warranty period of our machine is 12 months. Within the period, if machine problem is due to quality fault, we will replace parts for free. The moment we know the machine problem from customer, we will firstly tell the customer the fastest available schedule, then bring solution or send out parts as scheduled.

3.How can I get the after-service?

A: Any problem, you can contact us directly. We will send you spare parts for free if the problems caused by our machine during guarantee period. If problems are due to your wrong operations / maintenance, we also send the spare parts at your account.

4.How can I trust your company?

A: You can trust our 15 years experiences. You can see running machines in our customers’ plants. Old customers continuously buy machines from us for years.