Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

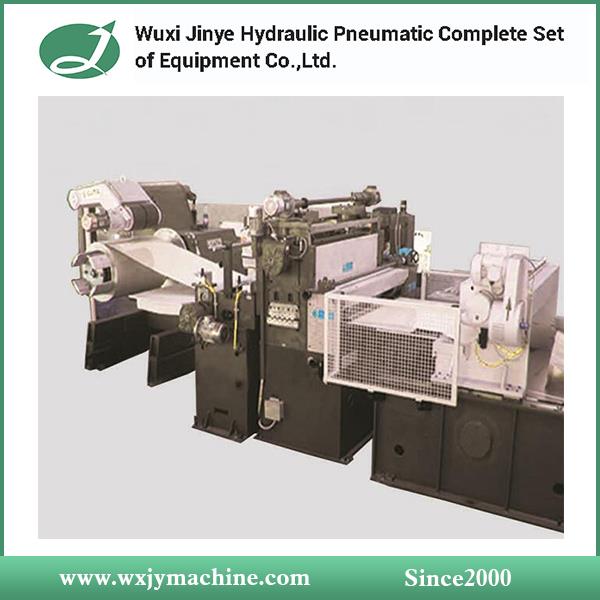

Compact thin sheet cut to length line with simple structure introduction When a steel plant wants a cut to length line to produce sheets for herself. First, the sheet is thin (thickness below 1.5mm). Second, the afterward sheet processing stage don’t require the cut sheet must be very flat....

Compact thin sheet cut to length line with simple structure introduction

When a steel plant wants a cut to length line to produce sheets for herself.

First, the sheet is thin (thickness below 1.5mm).

Second, the afterward sheet processing stage don’t require the cut sheet must be very flat.

Third, for self-use, don’t need big quantity of sheets(each day no more than 50T)

We suggest customers to have a compact cut to length line.

The simple cut to length line has simple but reliable structure, which cost a little in investment and occupy small space (no more than 15m x 3m area). Moreover, the line can be designed at 60m/min high speed or 30m/min normal speed.

Main features of the compact cut to length

1.Leveler is 2-hi structure, only upper leveling rollers and lower leveling rollers without backup.

2.The press-down of upper leveling rollers is manually adjusted.

3.The coil head opening and feeding is mainly achieved by the shaft motor of uncoiler.

4.Length fixing can be servo encoding style or normal rotary encoding style.

5.Shearing can be normal mechanical cutting or lower V-shape blade fast pneumatic shearing.

6.The cut sheet fall on automatic lifting table.

Main parameters

Model | Steel coil thickness range | Steel coil width range | Slitting speed (maximum) | Installation power |

JY-1.5x1000/1250 | 0.3-1.5mm | 300-1000/1250mm | 30m/min or 60m/min | 40KW |

Our Advantages

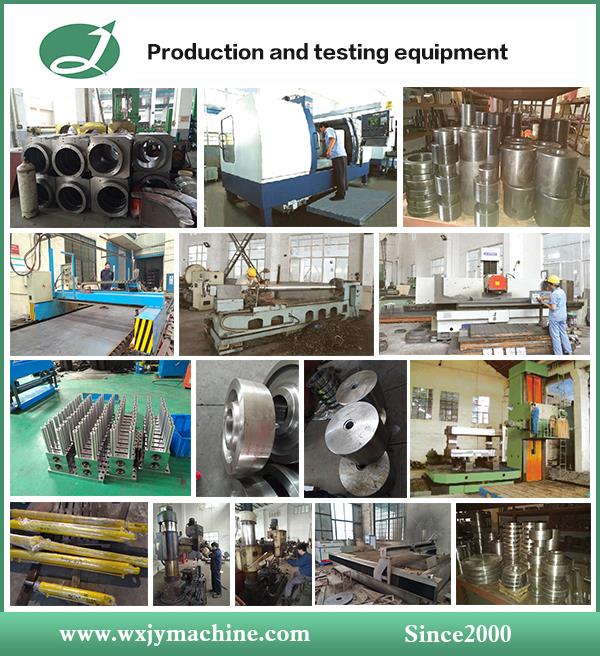

a. Extensive rich experiences:

We are specialized in the steel plate processing machines especially slitting machine & cut to length machines for over 15 years.

b. High quality raw material and standard parts:

We choose high quality materials from reliable supply channel.

We select famous parts like hydraulic valves, pneumatic parts, electric parts, bearings, bolts, etc. We are capable of designing and making the hydraulic system.

c. Strict testing procedures:

We check the parameters of each unit according to order details.

We test each motor, each electric cabinet, each valve.

We measure each machine dimensions and weight for shipment.

FAQ

1.Are you a manufacturer, trading company or a third party?

A: We are a manufacturer established in 2000.

2.If I will need to stay in your place for a few days, can you book hotel for me?

A: It is my pleasure to book hotel for you.

3.What is the delivery time of your machine?

A: The machine design and production need a production cycle. For small machine, usually 45-60days. For big machine and production line, usually 90days - 120days.

4.May I know What payment terms is accepted by your company?

A: So far, (30% advance + 70% balance) 100% T/T before shipment, or 30% deposit by T/T and balance by L/C.

5.Will you arrange the installation of the machine at site?

A: We can send technicians to customer’s plants to help install and debug machines. The customer should get installation conditions ready before our technicians come, buy round trip air tickets, provide food & lodging, and pay each technician 80usd per day. The installation takes about 20-30days.

6.How can I trust your company?

A: You can trust our 15 years experiences. You can see running machines in our customers’ plants. Old customers continuously buy machines from us for years.