Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

Heavy duty Thick Plate Slitting Line introduction Thick steel plate thickness ranges from 8mm to 14mm, thick plate slitting needs very heavy duty machine structure. We design heavy duty thick sheet slitting machine noting the below points 1.The coil head opening: portal frame has four strong...

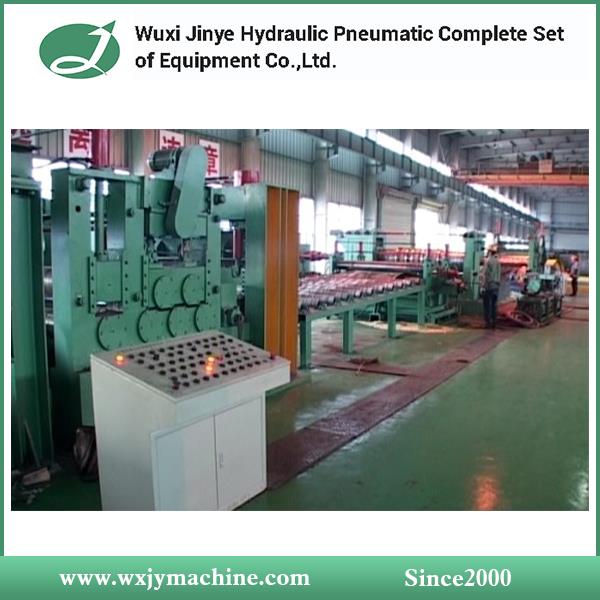

Heavy duty Thick Plate Slitting Line introduction

Thick steel plate thickness ranges from 8mm to 14mm, thick plate slitting needs very heavy duty machine structure.

We design heavy duty thick sheet slitting machine noting the below points

1.The coil head opening: portal frame has four strong steel section legs, traction wheel press down on top of coil, rotate to open coil head, then peeler tongue plate and coil-head straightener together guide the coil head enter pinch feeding rollers.

2.Heavy slitter: 200KW, 250KW DC motor and speed reducer & distribution gearbox, cascade universal joints, Ф140mm hydraulic cylinder pushes slitting stand of operation side out for changing slitting knives and spacers.

3.Five roller tensioner: 2 over 3 roller structure, hydraulic press-down, can provide enough strong recoiling tension and certain degree of flexibility.

4.Strong Portal structure separator pressing down from slit coils top: portal structure is independent frame, hydraulic press-down, adjustable with recoiling process, can make sure the recoiled coils are very neat and tight.

5.Dual-shift drive system is optional: when customers need to frequently slit thin steel coil and thick steel coil, we design and make dual-shift gearbox, this way, small thickness slitting can have higher speed and meanwhile, big thickness slitting don’t lack of power.

Machine Parameters

Model | Steel coil thickness range | Steel coil width range | Slitting speed (maximum) | Installation power |

JY-10x1800 | 2-10mm | 800-1800mm | 80m/min | 450KW |

JY-12x2000 | 3-12mm | 800-2000mm | 60m/min | 530KW |

JY-14x2000 | 3-14mm | 800-2000mm | 50m/min | 600KW |

Our performance

12 x 1250 slitting & CTL line

10 x 1600 slitting line in Egypt

Our service

Ø Provide the technical design and solutions;

Ø New plant construction guidance;

Ø Designing and manufacturing of non-standard equipment;

Ø Professional technical training and guidance on site according to the contract;

Ø Supply accessories at any time;

Ø Tele-technical consulting and services;

Ø Other special technical service according to client’s requirements.

Our Advantages

a. Extensive rich experiences:

We are specialized in the steel plate processing machines especially slitting machine & cut to length machines for over 15 years.

c. High quality raw material and standard parts:

We choose high quality materials from reliable supply channel.

We select famous parts like hydraulic valves, pneumatic parts, electric parts, bearings, bolts, etc. We are capable of designing and making the hydraulic system.

e. Delivery time:

The machine design and production need a production cycle.

For small machine, usually 45-60days.

For big machine and production line, usually 90days - 120days.

FAQ

1.What is the delivery time of your machine?

A: The machine design and production need a production cycle. For small machine, usually 45-60days. For big machine and production line, usually 90days - 120days.

2.Is your price competitive?

A: The priority is to supply reliable machine, different customers require different levels of machines, we make each machine according to each customer’s specific requirements. Based on confirmed specification, we give the most competitive price.

3.Where is your factory located?

A: Our factory address is: Meicun Industrial Park, New District, Wuxi City, Jiangsu Province, China.

4.If I will need to stay in your place for a few days, can you book hotel for me?

A: It is my pleasure to book hotel for you.