Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

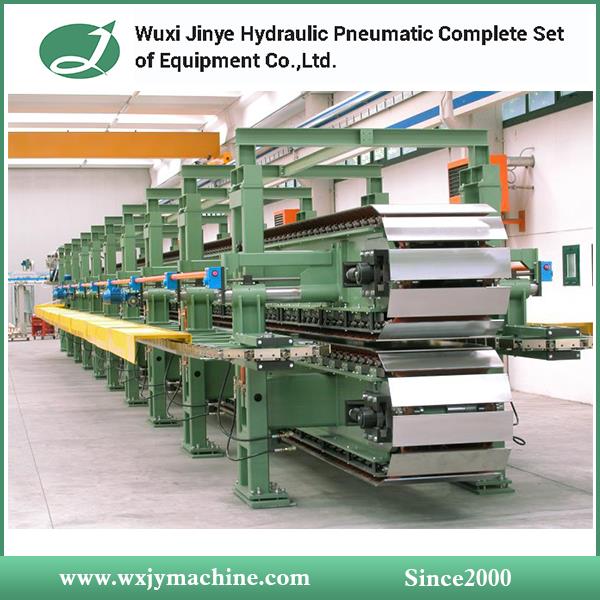

Decorative PU sandwich panel production line introduction The decorative PU sandwich panel production line includes metal coil decoiler embossing machine, lower plate forming machine(fast size change), PU foaming machine and PU injector, foil decoiler, sandwich board laminating machine(dual...

Decorative PU sandwich panel production line introduction

The decorative PU sandwich panel production line includes metal coil decoiler embossing machine, lower plate forming machine(fast size change), PU foaming machine and PU injector, foil decoiler, sandwich board laminating machine(dual track lamination machine), cutting to length shear, discharging table.

Input materials of the PU sandwich board lamination line

Material of lower plate: colored coil plate or aluminum coil plate

Material of upper soft foil: non-woven fabrics, kraft paper, aluminum foil

Material of core filling: polyurethane (PU)

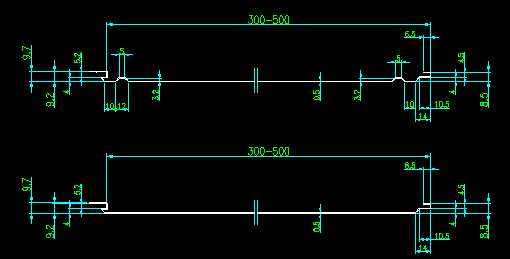

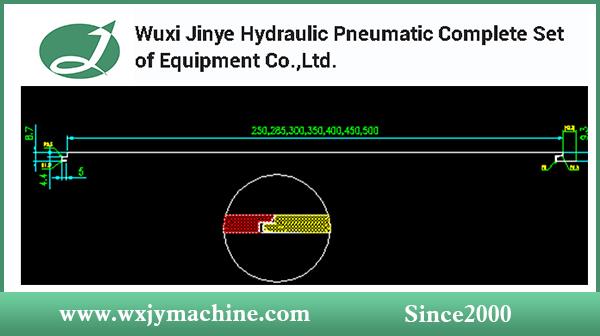

Lower coil plate width and thickness : 200-550mm 0.3-0.6mm

Finished PU composite laminated plates

Thickness of PU composite board: 10-16mm

Parameters of the PU laminated board line

Line speed of the PU laminating line: 2-6m/min

Total installation power: 100KW

Number of roll forming machines: two sets for inner decorative board, one set for exterior decorative board

Core machine

composite board laminating machine | Parameters |

length | 16m |

Motor | 2.2KW x 2 frequency motor |

transmission | By chains |

Press-down of upper track | hydraulic |

Track plate | Aluminum alloy 650 x 125mm |

Height of work line | 1000mm |

Hot wind blower | 40KW |

Temperature control | 20-50°C, infrared thermometer |

Our service

Ø Provide the technical design and solutions;

Ø New plant construction guidance;

Ø Designing and manufacturing of non-standard equipment;

Ø Professional technical training and guidance on site according to the contract;

Ø Supply accessories at any time;

Ø Tele-technical consulting and services;

Ø Other special technical service according to client’s requirements.