Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

Electric Steel Plate Cutting Machine introduction Electric steel plate, either oriented or non-oriented, (silicon content 0.8-4.8%) is thin with thickness usually below 1mm, is also called silicon steel plate. The process of making silicon steel sheets: first longitudinally slit big wide mother...

Electric Steel Plate Cutting Machine introduction

Electric steel plate, either oriented or non-oriented, (silicon content 0.8-4.8%) is thin with thickness usually below 1mm, is also called silicon steel plate.

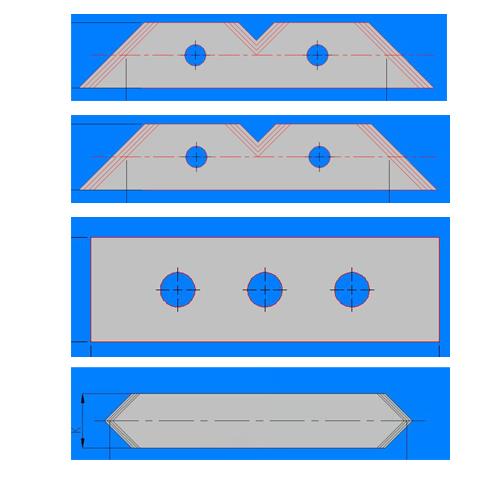

The process of making silicon steel sheets: first longitudinally slit big wide mother coil to be small coils, then transverse or chamfer cutting.

The longitudinal slitting line adopt compact slitting line technology, while transverse sheet cutting by servo feeding and cutting at very fast speed.

Moreover, the holes on silicon steel sheets are made by servo punching.

Productivity of the cutting line

| Sheet size | Speed(pcs/min) | Capacity(kgs per day) |

1 | Minimum 35mm width x 40mm length x 0.2mm thickness | 100pcs/min | 30kgs |

2 | Medium 100mm width x 500mm length x 0.3mm thickness | 50pcs/min | 1400kgs |

3 | Maximum 200mm width x 1200mm length x 0.35mm | 20pcs/min | 6000kgs |

Parameters

Material of coils: cold rolled oriented silicon steel coils

Coil thickness: 0.20-0.40mm

Coil width: 25-250mm

Finished Sheets length: 10-9999mm

Cutting tolerance: ±0.05mm/m at stable speed

Diagonal tolerance: ±0.05°

Shearing, punching burrs: oriented silicon steel ≤0.02mm, Non-oriented ≤0.03mm

Punch holes diameter: φ9-24mm

Max number of holes: 4pcs

Total installation power: about 9KW

Speed: about 121m/min

Application

Our Advantages

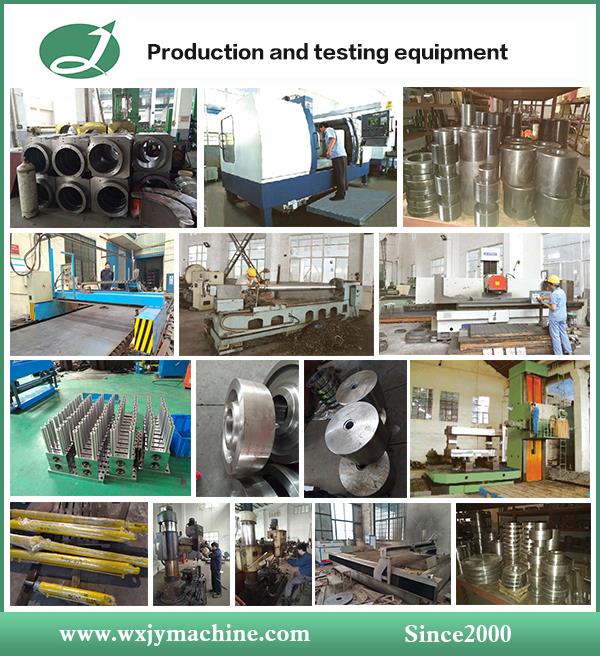

a. Extensive rich experiences:

We are specialized in the steel plate processing machines especially slitting machine & cut to length machines for over 15 years.

b. Fully customerized design and production:

Each machine is designed and made fully according to customer’s requirements, to reach complete customerization, we usually face to face discuss with customers confirming each technical detail, or communicate with customers by emails or online conversation with each technical document checked and confirmed by customers.

Our technicians make drawings of each machine according to signed specification.

The machining, heat treatment, grinding, assembly of each part are strictly processed under production schedule.

c. High quality raw material and standard parts:

We choose high quality materials from reliable supply channel.

We select famous parts like hydraulic valves, pneumatic parts, electric parts, bearings, bolts, etc. We are capable of designing and making the hydraulic system.

FAQ

1.If I will need to stay in your place for a few days, can you book hotel for me?

A: It is my pleasure to book hotel for you.

2.As the shipping period will take long time, how can you make sure the machine won’t be broken?

A: Our machine is film wrapped, to make sure the machine can be delivered to our customer in safe conditions, we fix the machine in the container by steel wires / ropes.

3.How can I get the after-service?

A: Any problem, you can contact us directly. We will send you spare parts for free if the problems caused by our machine during guarantee period. If problems are due to your wrong operations / maintenance, we also send the spare parts at your account.

4.Why choose us?

A: Our machine performances are the most convincing evidences for you to choose us. We achieve the performances by “careful, diligent” efforts day by day. Besides hard efforts, we know well what machines we can supply and what customers are suitable to use our machines. We would like to give our customers the best guidance and suggestions, to let customers know how to choose. To serve customers in this machine field is our mission, we are always here to serve, not far from you.