Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

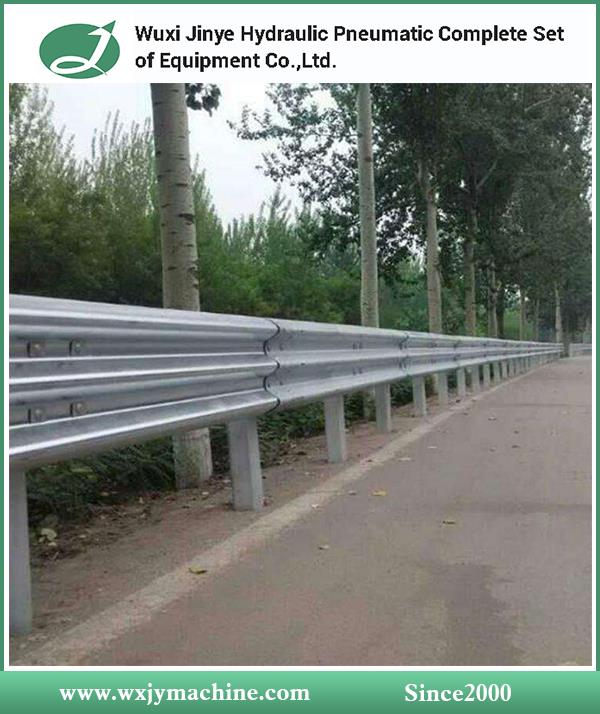

Guardrail roll forming machine introduction Guardrails roll forming machine is one of most popular roll forming machines, two wave or three wave guardrails are optional. Different countries have different standards of guardrails mounting, we design and make the guardrail forming machine...

Guardrail roll forming machine introduction

Guardrails roll forming machine is one of most popular roll forming machines, two wave or three wave guardrails are optional.

Different countries have different standards of guardrails mounting, we design and make the guardrail forming machine according to customer’s guardrail profile drawing.

31085 Two wave guardrail profile roll forming machine

Steel coil strip material:

Material: Q235

Steel strip thickness: 2.5~4.5mm

Steel strip width: 480mm

Coils ID, OD, weight φ508~φ600, ≤φ1900, ≤10T

Finished 2-wave Guardrails:

Example: 310mm width, 85mm height, 4320mm +/-2mm length

Guardrail machine:

Production speed: ≤15m/min 2 or 3 pieces per 4320mm

Total installation power: about 70KW

Work flow of the guardrail making machine:

Uncoiling, leveling, punching and cutting, feeding, roll forming, stacking

Main machine, GY230 roll forming machine:

1.11 forming stations, open portal stand structure with opening width up to 550mm

2.roller shafts: φ80mm, 40Cr quenching & tempering treatment.

3.Drive: 9pcs gearboxes connect to lower roller shafts, ZQ500 speed reducer ratio 31.5, drive motor 37KW AC motor.

4.Forming rollers: material GCr15, wholly quenched with surface hardness HRC58-62.

Punching & Cutting machine, Four pillar hydraulic Press puncher:

Hydraulic cylinder for punching ¢160mm x 60mm Brand: Yangli

50685 Three wave Guardrail roll forming machine

Steel coil strip material:

Material: Q235 hot rolled

Steel strip thickness: 2.5~4.5mm

Steel strip width: 750mm

Coils ID, OD, weight φ508~φ600, ≤φ1900, ≤10T

Finished 3-wave Guardrails:

506mm width, 85mm height, 4320mm +/-2mm length

Guardrail machine:

Production speed:≤15m/min 2 or 3 pieces per 4320mm

Total installation power: about 100KW

Work flow of the guardrail making machine:

Uncoiling, pinch feeding & leveling, punching and cutting, feeding, roll forming, stacking

Main machine, GY250 roll forming machine

1. 15 forming stations, open portal stand structure with opening width up to 750mm

2. roller shafts: φ110mm, 40Cr quenching & tempering treatment.

3.Drive: 13pcs GY230 M12 gearboxes connect to lower roller shafts, ZQ650 speed reducer ratio 31.5, drive motor 55KW AC motor. Between gearboxes and between roller shafts connect with sprockets and chains.

4.Forming rollers: material GCr15, wholly quenched with surface hardness HRC58-62.

Punching & Cutting machine, Four pillar hydraulic Press puncher

Hydraulic cylinder for punching ¢180mm x 60mm Brand: Yangli

Steel Profiles are widely used in many industries such as construction, house decoration, solar energy mounting system, elevators, automobiles, etc. We design and make steel profile roll forming machines according to client’s profile drawings. The popular profiles as below:

Roofing panel forming machine

C,Z purlin roll forming machine

Guardrail cold forming line

Culvert corrugated panel forming machine

Elevator parts cold forming machine

Photovoltaic stent roll forming machine

Cable tray roll forming machine

Scaffold foot plate forming machine

Racking profiles forming machine

Control system

Encoder length fixing, PLC + HMI operation panel

Our service

Ø Provide the technical design and solutions;

Ø New plant construction guidance;

Ø Designing and manufacturing of non-standard equipment;

Ø Professional technical training and guidance on site according to the contract;

Ø Supply accessories at any time;

Ø Tele-technical consulting and services;

Ø Other special technical service according to client’s requirements.

FAQ

1.What is your minimum order quantity, can you send me samples?

A: Our minimum order is 1 set machine, each machine is customerized, thus we don’t have sample to send, however, we can send you catalog, warmly welcome you to visit our company.

2.What is the delivery time of your machine?

A: The machine design and production need a production cycle. For small machine, usually 45-60days. For big machine and production line, usually 90days - 120days.

3.As the shipping period will take long time, how can you make sure the machine won’t be broken?

A: Our machine is film wrapped, to make sure the machine can be delivered to our customer in safe conditions, we fix the machine in the container by steel wires / ropes.