Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

More rolling mills introduction We have rich experiences in metal coil cold rolling mill design and manufacture, cold rolling mill is for reducing metal coil plate thickness by cold rolling, therefore, also can be called “thickness reducing mill” or “gauge reducing mill”. Stainless Steel Coil...

More rolling mills introduction

We have rich experiences in metal coil cold rolling mill design and manufacture, cold rolling mill is for reducing metal coil plate thickness by cold rolling, therefore, also can be called “thickness reducing mill” or “gauge reducing mill”.

Stainless Steel Coil Cold Rolling Mill

Stainless steel coil is very hard and require high precision and clean rolling.

Stainless steel coil rolling requires much stronger rolling force and recoiling tension, and the rolling speed is limited not going up too high.

Ø455×750/Ø650×720 4-Hi cold rolling mill

Input material:

Input material:

low carbon steel HR pickled coils

Input steel strip: 2.0~3.0×500~680 mm

Inner diameter and outer diameter of steel coils: φ508/φ1600mm, max 8T

Finished coil after rolling:

Finished coil after rolling:

Finished strip: thickness: (0.2~1.0)×(500-680)mm

Parameters of the 750 cold rolling mill:

Parameters of the 750 cold rolling mill:

Max rolling force: 8000 KN

Rolling speed: max 150 m/min

Recoiling speed: max 160 m/min

Recoiling force: 130 KN

Diameter of recoiling mandrel: max 508 mm , min. 495 mm

Height of rolling mill workline: 1000 mm

Total installation power: about 1700 KW

Aluminum Plate Reversible Cold Rolling Mill

Reduce aluminum billet plate thickness to certain thickness by reversible rolling.

Ø280×1250/Ø680×1200 4-Hi cold rolling mill

Material of aluminum plate: 1xx series, 3xx series

Input: (4-8)mmx1100mm x <1000mm

Output: (0.5-3)mmx1100mm x <3000mm

Rolling speed: 0-30m/min

Thickness reducing degree:≤35% h per pass

Rolling force: P≤6000kN

Rolling precision: flat without obvious deflection and wave.

Skin Pass Mill (Leveling & Tensioning Cold Rolling Mill)

Skin pass mill can be 2-Hi or 4-Hi structure, to improve the steel strip by S tensioning rollers and rolling mill. The flatness of cold rolled steel strip is not so good after annealing, skin pass line can largely diminish yield platform and improve the mechanical properties of annealed steel strips.

Composition of the skin pass line:

Coil loading car, uncoiler, pinch feeder, shear & welder

S tension roller, skin pass rolling mill, S tension roller, pinch feeder and shear, recoiler, discharge car.

Example parameters:

Raw Material:

Thin gauge cold rolled annealed steel coil strips σS≤400 MPa

Thickness, width :0.3~2.0×400 mm

Coil ID, OD, max weight: 508mm, 1600mm, 5T

Max rolling force: 2500KN

Recoiling tension: 15KN

Skin pass speed: max 180m/min

Recoiling speed: max 180m/min

Elongation: 0.3-1.5%

Total Power: 500KW

Our Advantages

a. Fully customerized design and production:

Each machine is designed and made fully according to customer’s requirements, to reach complete customerization, we usually face to face discuss with customers confirming each technical detail, or communicate with customers by emails or online conversation with each technical document checked and confirmed by customers.

Our technicians make drawings of each machine according to signed specification.

The machining, heat treatment, grinding, assembly of each part are strictly processed under production schedule.

b. High quality raw material and standard parts:

We choose high quality materials from reliable supply channel.

We select famous parts like hydraulic valves, pneumatic parts, electric parts, bearings, bolts, etc. We are capable of designing and making the hydraulic system.

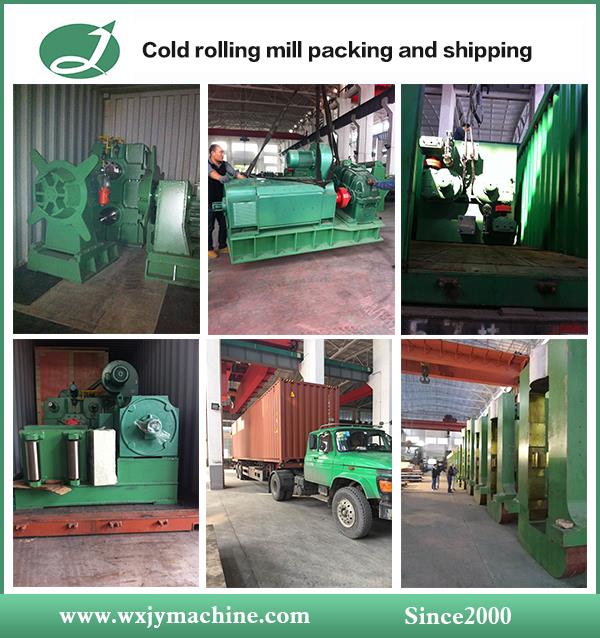

c. Safe packing:

Anti-rust oil be spread on machines before shipping.

Electric cabinets covered with plastic bag.

Small parts, valves, hoses are packed in wooden case.

FAQ

1.Are you a manufacturer, trading company or a third party?

A: We are a manufacturer established in 2000.

2.Where is your factory located?

A: Our factory address is: Meicun Industrial Park, New District, Wuxi City, Jiangsu Province, China.

3.How can I get to your factory?

A: Our city Wuxi is near to Shanghai. You can get off plane at Pudong or Hongqiao airport in Shanghai, then come to Wuxi by fast train for 40minutes. You can take fast train from Beijing to Wuxi, 5 hours. You can come to Wuxi Shuofang Airport by plane. We can pick you up from Wuxi stations, airport, even in Shanghai airport.

4.If I will need to stay in your place for a few days, can you book hotel for me?

A: It is my pleasure to book hotel for you.