Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

High precision small pipe mills introduction Welded Pipe Production Lines (Straight Pipe Welding Line, Pipe making machine, ERW pipe mill, ERW pipe welding line, High frequency pipe welding equipment). We supply high frequency welded pipe production lines, which continuously make certain length...

High precision small pipe mills introduction

Welded Pipe Production Lines (Straight Pipe Welding Line, Pipe making machine, ERW pipe mill, ERW pipe welding line, High frequency pipe welding equipment).

We supply high frequency welded pipe production lines, which continuously make certain length of steel pipes by roll forming, high frequency welding, section sizing, longitudinal straightening, flying cutting and discharging from steel coil strips.

According to the sizes (wall thicknesses and diameters) of finished pipes, we design and make the whole production line, which include uncoiler, shear & welder, accumulator(cage style or spiral style), forming-welding-cooling-sizing-straightening machine, flying saw and discharging roll table.

Generally speaking, the following pipe welding line models are available:

Features of our small pipe mills

1.Small Pipes usually are thin gauge small diameter pipes, requiring high profile precision and high producing speed.

2.Double arms uncoiler, 180°rotating, with one coil uncoiling and another coil loading on the other arm.

3.Pneumatic shear & welder, to connect tail of last coil and head of new coil.

4.Cage accumulator(cage loop): to accumulate hundreds of meters steel strip to ensure continuous pipe making.

5.One pair of vertical roller guide and seven roller passive leveler.

6.Forming mill(Eight sets horizontal drive rollers and 8 sets vertical passive rollers) form steel strip to be pipe blank.

7.Welding table(small rotary seam guide, a pair of vertical squeeze rollers, two sets outer scraper, one set polishing rollers.

8.Cooling tank: spray cooling and immerse cooling.

9.Sizing mill(seven sets horizontal drive rollers and seven sets vertical passive rollers): shape the formed welded pipe to be exact profile.

10.Turks head(single side or double sides on one head): rotary adjust to straighten the pipe.

11.Flying saw(hot friction cutting or cold cutting): synchronously track the running pipe and cut to certain length.

12.Discharging roll table(double sides): discharge the finished pipes to stacking area.

13.High frequency welding equipment(solid state): heat both edges of pipe blank to melt by high frequency induction welding.

14.Electric control: from uncoiling to accumulating, one operator panel; forming, welding and sizing on another operator panel; flying saw and discharging table, the third operator panel.

15.For galvanized pipes, zinc patching equipment is installed after outer bur scraping and before cooling.

Parameters of small pipe making mills

Model | Pipe size | HF welder (KW) | Motor power(KW) | Speed (m/min) |

HG16 | Ф(7-20) x (0.2-0.5) | 60 | 22 | 80-140 |

HG25 | Ф(8-32)x(0.35-1.3) | 100 | 45 | 70-130 |

HG32 | Ф(15-50) x (0.6-2.0) | 150 | 110 | 60-120 |

HG50 | Ф(20-63)x(0.8-2.5) | 200 | 160 | 50-100 |

HG63 | Ф(20-76)x(0.8-3.0) | 250 | 200 | 30-90 |

Our Advantages

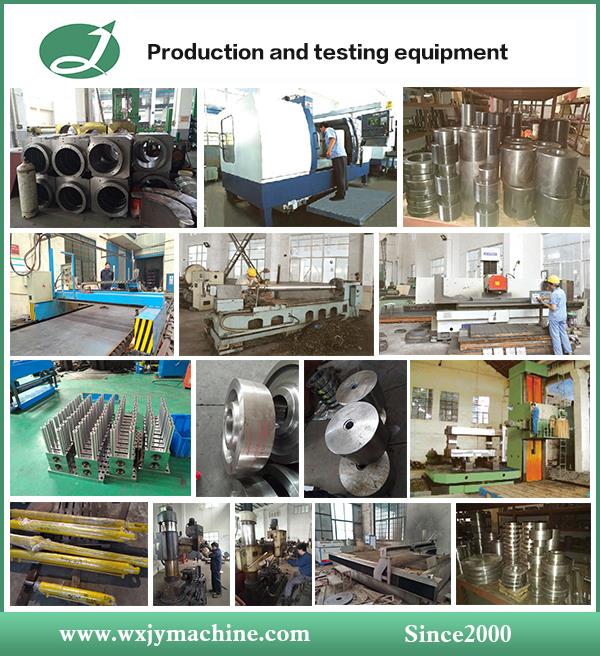

a. Extensive rich experiences:

We are specialized in the steel plate processing machines especially slitting machine & cut to length machines for over 15 years.

b. High quality raw material and standard parts:

We choose high quality materials from reliable supply channel.

We select famous parts like hydraulic valves, pneumatic parts, electric parts, bearings, bolts, etc. We are capable of designing and making the hydraulic system.

c. Strict testing procedures:

We check the parameters of each unit according to order details.

We test each motor, each electric cabinet, each valve.

We measure each machine dimensions and weight for shipment.

FAQ

1.Where is your factory located?

A: Our factory address is: Meicun Industrial Park, New District, Wuxi City, Jiangsu Province, China.

2.Which level of quality are your products?

A: We don’t say our machine quality is the best, our aim is to supply most suitable machine at most reasonable price. “functional, safe, economical” principles keep our company everlasting.

3.As the shipping period will take long time, how can you make sure the machine won’t be broken?

A: Our machine is film wrapped, to make sure the machine can be delivered to our customer in safe conditions, we fix the machine in the container by steel wires / ropes.

4.About the after-sale service, how can you solve the problems occurred of your overseas customer in time?

A: The warranty period of our machine is 12 months. Within the period, if machine problem is due to quality fault, we will replace parts for free. The moment we know the machine problem from customer, we will firstly tell the customer the fastest available schedule, then bring solution or send out parts as scheduled.