Introduction:

Thick plate cut-to-length line can meet customer's request of max line speed 20m/min by uncoiling and leveling a coil strip, and then shearing the leveled flat strip to certain length of sheets.

The cut-to-length line (plate CTL line machine) has one pre-leveling machine and one fine leveling machine driven by DC or AC motors, and the length-fixing is by encoder, shearing style is stop-shear.

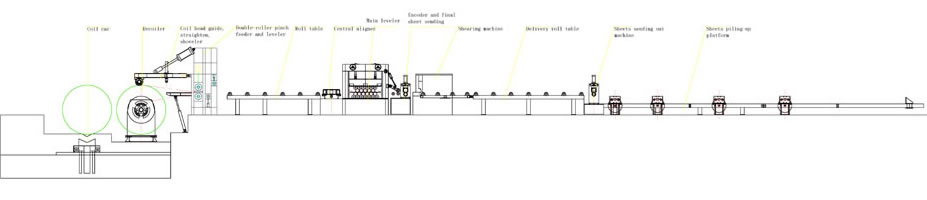

The thick plate cut-to-length line is composed of: coil loading car, Double-mandrel decoiler, Portal-style coil-head guide, press & shoveling equipment, pinch-feeding & pre-leveling, transmit table,(side guide, edge trimmer, edge scrap winder, transmit table), side guide, Main Leveling machine, Final sheet sending out equipment, length-fixing encoder, Hydraulic shearing machine, delivery roll table & plates-sending-out equipment, pneumatically piling-up table, hydraulic system, electric control system, etc.

The thick plate cut-to-length line (plate CTL line machine) fit steel coils with thickness: (3~12mm, 4~16mm, 5-20mm) and changeable width, and length of finished sheets depend on customer's practical need.

Advantages & Characteristics of Plate CTL Machine:

1. Plate CTL line machine with High precision

Line speed can be up to 20m/min, 4-5pcs/min 2000mm Length sheets in average.

Leveling precision: ±1.5mm/㎡

Sheet length precision: ±0.5mm/m

Sheet diagonal length precision: ±1mm/m

2. Weight of thick plate coils is heavy up to 30T, 35T or 40T, double-cone decoiler is proper.

3. Strong portal-style coil-head opener including coil-head guide, press and shoveler can make sure decoiling smoothly going on.

4. To make flat steel sheets, the diameter of leveling rollers should be scientifically proper, we confirm diameter of leveling rollers by actual experiences and engineering calculation when processing the plate cut-to-length line.

5. The backup rollers installed in backup bracket can tightly back leveling rollers up to make sure no deformation of leveling rollers while leveling.

6. Twice leveling is arranged in the thick plate cut-to-length line, to ensure good leveling effect.

Customer can choose to include edge trimmer, to trim off the useless edges.

7. Final-sheet sending-out equipment sends finished sheets onto pneumatic packing table.

8. We adopt good quality parts for the plate CTL line machine supplied by famous brand company, e.g. Mitsubishi PLC control, Yuken/Fuxin hydraulic parts, HRB/ZWZ/SKF bearings,etc

Input material: CR, HR carbon steel coils, GI, PPGI steel plates.

1. YJ-(3~12)×1600mm/2000mm/2500mm Thick Plate Cut to Length Line

Plate CTL line machine Strip thickness: 3~12mm

Strip width: 600~1600mm, 800-2000mm, 1100-2500mm

Leveling roller: Φ180, 13pcs

Material of leveling roller: 40Cr, HRC55-56

Power for leveling: 132KW DC motor + Eurothem 590 DC speed control

Plate CTL line machine Cutting speed: (0~20) m/min, adjustable

Plate CTL line machine Power for leveling: 160KW DC motor + Eurotherm 590 DC speed control.

Cutting speed: (0~20) m/min, adjustable

Power for leveling: 110KW+160KW DC motor + Eurothem 590 DC speed control.

Plate CTL line machine Cutting speed: (0~20) m/min, adjustable

|

Detail specification: Model |

thickness | width | Length | Leveling speed |

| JY-12 x 1600 | 3.-12mm | 600-1600mm | adjustable | Max 20m/min |

| JY-16 x 1800 | 4-16mm | 1000-1800mm | adjustable | Max 20m/min |

| JY-20 X 2000 | 5-20mm | 1000-2000mm | adjustable | Max 20m/min |

| Note: The data in the form just as reference according to general ranges, we always design and make each thick plate cut-to-length line,plate CTL line machine according to each customer's specific requirements, so each customer can buy his own well-content line from us. | ||||