Introduction:

When you want to (Decoil-Slit-Recoil) and (Decoil-Level-CTL) in one production line, we can design and produce combined slitting and cut-to-length line for you. We have succeeded in making such combined production line for domestic and foreign customers.

The composition of combined slitting and CTL line is in accordance with customers' specific requirements and actual conditions.

Combined Slitting Cut-to-length Line Layout:

Usually, two kinds of layout flow can be as reference:

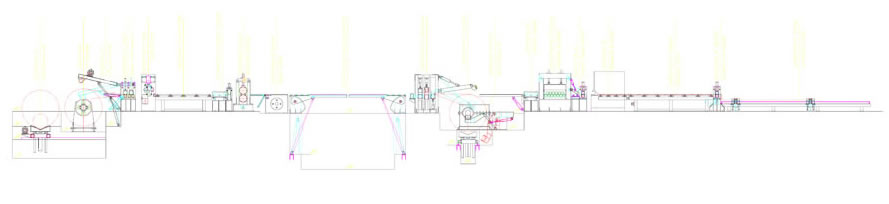

1. First, slitting line; then cut-to-length line:

Coil loading car, decoiler, coil-head guide, press and shovel equipment, pinch feeder and leveler, coil-head shear, hole accumulator(transmit table), side guide, slitter, scrap winder, hole accumulator, pre-separator and tensioner, separator & recoiler, transmit table, side guide, leveler, encoder(final-plate pinch feeder), shearing machine, delivery table, stacker.

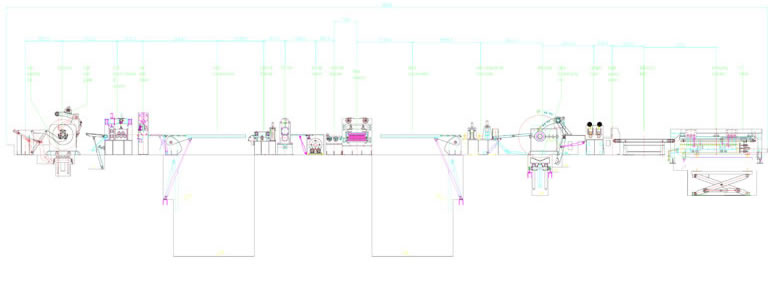

2. Harmonize slitting and cut-to-length line into one production line

Its layout can be as follows:

Coil-loading car, uncoiler, Coil-end-guide and shoveling equipment, Double-roller pinch feeder & five-roller leveler, End-cutting, hole accumulator(transmit table), Central-aligner and Horizontal presser, Slitter, Scrap winder, Central aligner, Leveler, Hole accumulator, Tensioner, Pre-separator, Separator, Recoiler, coils discharging car, length-fixer, Shearing machine, Delivery table, stacker.