Add: Wuxi City, Jiangsu Province, Umemura Industrial Park Road 9 Zhang Road

Contact: Yan Yanjun

Tel: +86-510-81819377

Mob: +86-18951513765

Fax: +86-510-88159195

E-mail: globalsales2013@gmail.com

Culvert corrugated panel roll forming machine introduction Culvert has two styles: one whole round style and assembled style.The assembled style culvert is flexible to change culvert diameter according to actual situation.Steel Profiles are widely used in many industries such as construction,...

Culvert corrugated panel roll forming machine introduction

Culvert has two styles: one whole round style and assembled style.The assembled style culvert is flexible to change culvert diameter according to actual situation.Steel Profiles are widely used in many industries such as construction, house decoration, solar energy mounting system, elevators, automobiles, etc. We design and make the corrugated panels to be used to assemble culverts.

The making process of the corrugated panels

Uncoiler, leveling, cut to length, servo feeding, punching, roll forming, semi-finished product, camber bending, finished product.

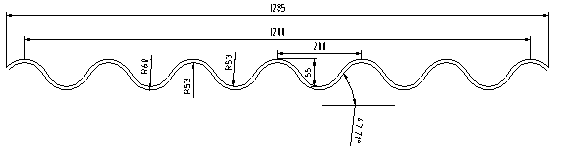

Technical parameters of the corrugated panels production

Coil width: ≤ 1510 mm

Coil thickness: 3.0-8.0mm

Raw material: low carbon steel, CR, galvanized plate

Cutting length: According to customer

Product: Corrugated panel (based on customer's drawing)

|

Precision control |

|

|

Corrugated panel width tolerance |

±3.0 mm |

|

Corrugated panel length tolerance |

±3mm |

|

Pitch tolerance of sinus wave |

±0.5mm |

|

Depth tolerance of sinus wave |

±1.5 mm |

|

Height tolerance of two peaks farthest to each other |

±2.0mm |

|

Tolerance of distance between all punching holes |

±1.5mm |

production speed: Time for every piece plate=number of holes *8s+60s

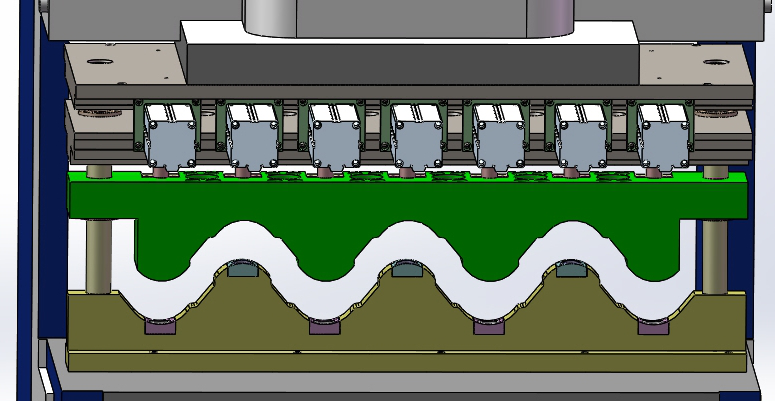

Main machine: corrugated pane forming machine

1.25 forming steps, composed of AC speed-regulating motor, speed reducer, transmission gearboxes, forming shafts & rollers, cast iron portal stands and machine base

2.The machine base and 24 transmission gearboxes are welding assembly, with stress relieving treatment. 45# M16 gears of hardened teeth face in the 24 transmission gearboxes, connect to ¢180mm roller shafts by universal joints of square body(90mm x 90mm)

3.Combined rollers have advantages of less speed difference & forming resistance, to ensure forming precision without scratching plate surface.

Forged GCr15 rollers, wholly quenched, CNC machining surface, HRC58-60, with features of high strength, high hardness, high precision and long life span.

4. Two sets 90KW DC motor, speed reducer and transmission gearboxes

Drive the bottom roller shafts, less slipping between rollers and steel plate can reduce plate surface (esp. galvanized steel, stainless steel) damage.

5.Machine model: GY300 about 25 stations

motor: Z4-225-31-90kwDC motor, 2sets

speed reducer: ZS950, ratio:100,2sets

roller shaft diameter: ¢180mm

Max feeding width: 1510mm

forming rollers: according to customer

brake: ¢300 brake wheel, electromagnetic

Main machine: Camber bending machine

1.Machine base: closed portal structure and support bracket of four rollers, with stiffened plates. Vibration and tempering treatment remove inner stress of machine base, to ensure enough precision and rigidity.

2.Independently or synchronously the top two rollers contact the bottom two rollers always at point of tangency, thus effectively avoid the straight end defect of arc bent corrugated panel.

3.Four rollers of sinus wave are driven by motors, synchronously rotating in stability.

4.Up-down linear movement of wave rollers are driven by mechanical motor lifting support brackets where roller ends are installed. Support brackets are separate, synchronously linear move.

5.Linear moving distance is mechanically positioned in high precision.

6.GCr15 200 x 56wave rollers, high frequency quenching treatment.

FAQ

1.How can I get to your factory?

A: Our city Wuxi is near to Shanghai. You can get off plane at Pudong or Hongqiao airport in Shanghai, then come to Wuxi by fast train for 40minutes. You can take fast train from Beijing to Wuxi, 5 hours. You can come to Wuxi Shuofang Airport by plane. We can pick you up from Wuxi stations, airport, even in Shanghai airport.

2.Why choose us?

A: Our machine performances are the most convincing evidences for you to choose us. We achieve the performances by "careful, diligent" efforts day by day. Besides hard efforts, we know well what machines we can supply and what customers are suitable to use our machines. We would like to give our customers the best guidance and suggestions, to let customers know how to choose. To serve customers in this machine field is our mission, we are always here to serve, not far from you.